Top Support Solutions for Construction and Outdoor Projects

In the world of building and outside jobs, the selection of support systems is critical for ensuring safety and architectural honesty. With a variety of alternatives offered, varying from standard concrete supports to ingenious ground screws, each system provides one-of-a-kind benefits and considerations. The performance of these systems can dramatically affect project results, making it important to examine elements such as lots ability, environmental conditions, and setup methods. As we check out the top recommendations, it comes to be clear that the best selection can make all the distinction in achieving ideal efficiency and reliability.

Sorts Of Support Equipments

Support systems work as the foundation of building security, giving vital assistance for frameworks in various environmental problems. Comprehending the various kinds of support systems is essential for picking the appropriate service for particular jobs.

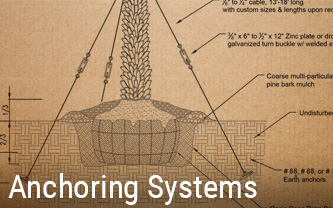

There are mostly 3 classifications of support systems: driven, drilled, and cast-in-place supports. Driven anchors, including concrete nails and steel stakes, are set up by hammering them into the ground, making them appropriate for lightweight applications or short-term structures. Drilled anchors, such as helical and growth anchors, are inserted into pre-drilled holes, permitting better tons capacity and security, ideal for applications in difficult soils. Cast-in-place anchors, typically made use of in concrete applications, are integrated during the pouring of concrete, giving strong, permanent assistance for hefty frameworks.

Additionally, the selection of products plays an important function in anchor system performance. Typical materials consist of steel, stainless-steel, and polymers, each using different degrees of deterioration resistance and toughness. Picking the best type of anchor system is important to ensure safety and security, durability, and efficiency in various construction and outside projects.

Factors to Think About

Following, the environmental conditions need to be assessed. Factors such as soil kind, dampness levels, and capacity for corrosion can substantially influence support efficiency and long life. In addition, the anticipated installation deepness and anchorage demands need to be taken into consideration to ensure security.

The convenience of installment and removal is another essential element. Some projects might need constant repositioning of supports, making systems that enable quick changes preferred.

In addition, security standards and laws particular to the building and construction site should be stuck to, making sure conformity with regional codes.

Lastly, spending plan restrictions will undoubtedly contribute in the decision-making process. Stabilizing cost with performance and safety and security is essential to attaining project objectives without jeopardizing high quality. By attentively assessing these factors, building professionals can choose the most suitable anchor system for their specific requirements.

Leading Anchor System Recommendations

Picking the right support system is crucial for making certain architectural integrity and security in building and construction projects. Various anchor systems deal with various applications, and understanding their toughness is necessary for optimal efficiency.

One extremely recommended alternative is the Hilti HUS-3 expansion anchor, known for its high load-bearing capability and flexibility in concrete applications. Its simplicity of installment makes it suitable for both experts and DIY enthusiasts.

Another exceptional selection is the Simpson Strong-Tie Titen HD. Earth Anchor, which supplies exceptional holding power in different products, consisting of concrete and masonry. Its one-of-a-kind design reduces the danger of concrete outbreak, making it suitable for durable applications

For outside jobs, the Screw-in Ground Support systems, such as those from Zareba, provide phenomenal stability in dirt conditions. These supports are made to withstand significant side and upright tons, making them ideal for fencing and other outside structures.

Lastly, think about the 3M DBI-SALA anchor factors for loss defense. These systems are crafted for safety, providing reliable anchorage services on rooftops and elevated surfaces.

Choosing the ideal support system can substantially affect the success and safety of any type of building venture.

Installment Tips

Appropriate installation of anchor systems is vital for attaining optimal efficiency and safety and security in building and construction jobs. To make sure effective anchorage, begin by selecting an ideal anchor type based upon the task's certain demands, such as lots ability and ecological conditions.

Prior to setup, examine the substrate to validate its suitability. This consists of checking for integrity, dampness levels, and any kind of possible pollutants that could influence adhesion. Make use of the proper tools and tools recommended by the support supplier for optimal outcomes.

Usage ideal securing techniques, whether glue or mechanical, and allow for proper curing time when using chemical anchors. It is a good idea to perform pull-out examinations to verify the anchor's holding capability before applying any considerable loads.

Maintenance and Safety Tips

To guarantee the long life and performance of support systems in building, routine upkeep and adherence to safety and security methods are essential. Inspect support systems consistently for indicators of hop over to here damage, corrosion, or wear. This consists of monitoring for loose screws, fractures in concrete, or degeneration in materials. Any kind of endangered elements ought to be changed right away to stop failure during procedure.

Correct cleaning is also crucial; debris and pollutants can impair the capability of the anchor system. Usage non-corrosive cleaning representatives and make sure that all parts are extensively dried out to avoid moisture-related problems.

Safety and security procedures should be purely followed during installment and use. Ensure that all employees are trained in anchor system requirements and constraints, using proper individual protective devices (PPE) whatsoever times. Conduct danger analyses before beginning work to determine possible threats connected to support systems.

Additionally, preserve exact documents of evaluations and upkeep activities. This not just ensures compliance go to my site with sector standards however likewise gives important information for future projects. By prioritizing maintenance and safety, construction experts can improve the reliability and efficiency of anchor systems, ultimately resulting in safer and a lot more successful jobs.

Verdict

Finally, choosing the proper support system is vital for accomplishing structural honesty and safety and security in building and construction and exterior jobs. Varied alternatives, such as the Hilti HUS-3 and Simpson Strong-Tie Titen HD for concrete applications, as well as screw-in ground supports for dirt security, deal customized services to specific requirements. Sticking to setup and maintenance guidelines better guarantees ideal performance and safety and security, eventually contributing to the success and durability of numerous tasks.

In the realm of building and construction and exterior jobs, the selection of support systems is critical for making certain safety and security and structural honesty.There are mostly three classifications of anchor systems: driven, pierced, and cast-in-place anchors. Pierced supports, such as helical and Going Here growth anchors, are placed into pre-drilled openings, enabling for higher lots capability and security, suitable for applications in challenging dirts. Selecting the appropriate type of support system is crucial to guarantee security, longevity, and efficiency in different building and outdoor jobs.

In verdict, choosing the proper anchor system is essential for accomplishing architectural integrity and safety and security in building and exterior projects.